| Availability: | |

|---|---|

| Quantity: | |

Round Nut DIN 548 Adjustable Fixing Ring

Crafted to meet DIN, ASTM, and ISO standards, our heavy hex slotted nuts deliver reliable fastening performance for critical industrial applications. Available in sizes from M8 to M68, these nuts are manufactured from high-tensile carbon steel (Grade 8.8/10.9) or corrosion-resistant stainless steel (304/316), with optional zinc plating for enhanced protection.

Technical Specifications:

✔ Material Excellence

Carbon Steel: Grade 10.9 (ISO 898-1) | Yield Strength: 940 MPa

Stainless Steel: 316 (ASTM A193) | Salt Spray Resistance: 1000+ hours

Zinc Plating: 5-8μm coating thickness (ISO 4042)

✔ Precision Threading

Thread Standards: UNC, UNF, BSW

Slot Width: ±0.1mm tolerance

Dimensional Compliance: DIN 981 / ASTM A563

Industrial-Grade Performance:

Vibration Resistance: Nord-Lock washer compatibility

Temperature Range: -50°C to +300°C (stainless steel version)

Certifications: ISO 9001, CE, SGS (batch-tested)

Typical Applications:

• Power transmission tower assembly

• Heavy machinery maintenance

• Structural steel connections

Why Choose Our Nuts?

Material Flexibility: From economy carbon steel to marine-grade stainless

Custom Solutions: Laser etching, special coatings, and non-standard sizes

(Standard packaging: 25kg cartons | Custom packaging available)

Q & A

1. Q: What Types of Your Company?

A: We're a foreign company with our own factory. That is, an integrated set of industry and foreign trade.

2. Q: What Types that Your Company's Manufacturing?

A: OEM/ODM, logo printing and new product's volume production.

3. Q:What's Your Main Products?

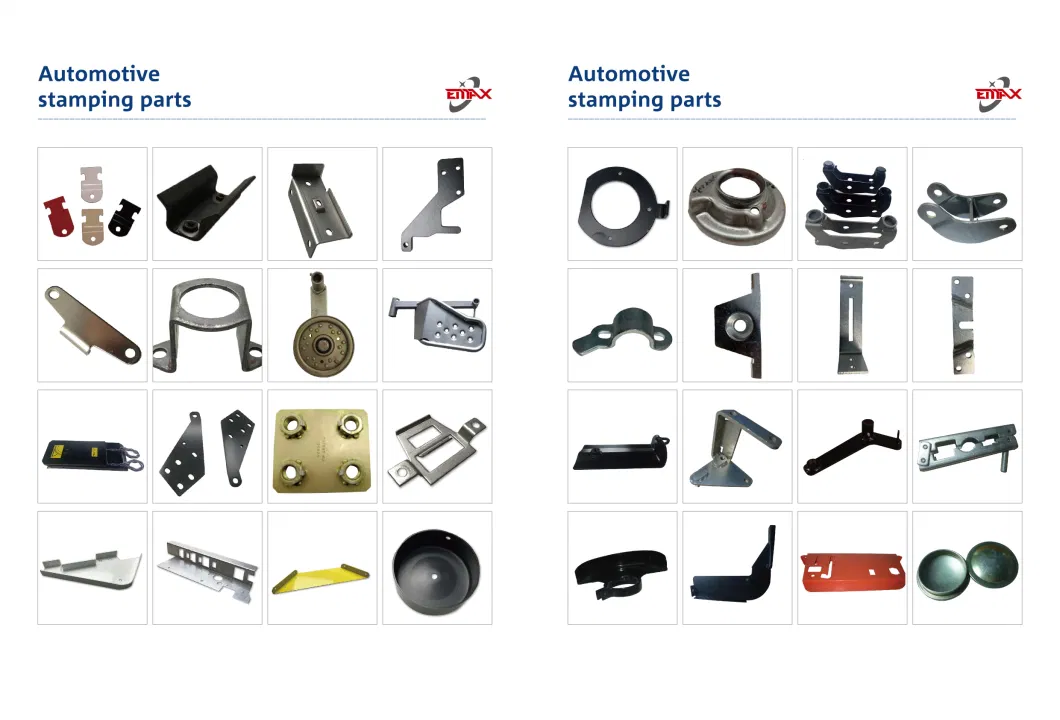

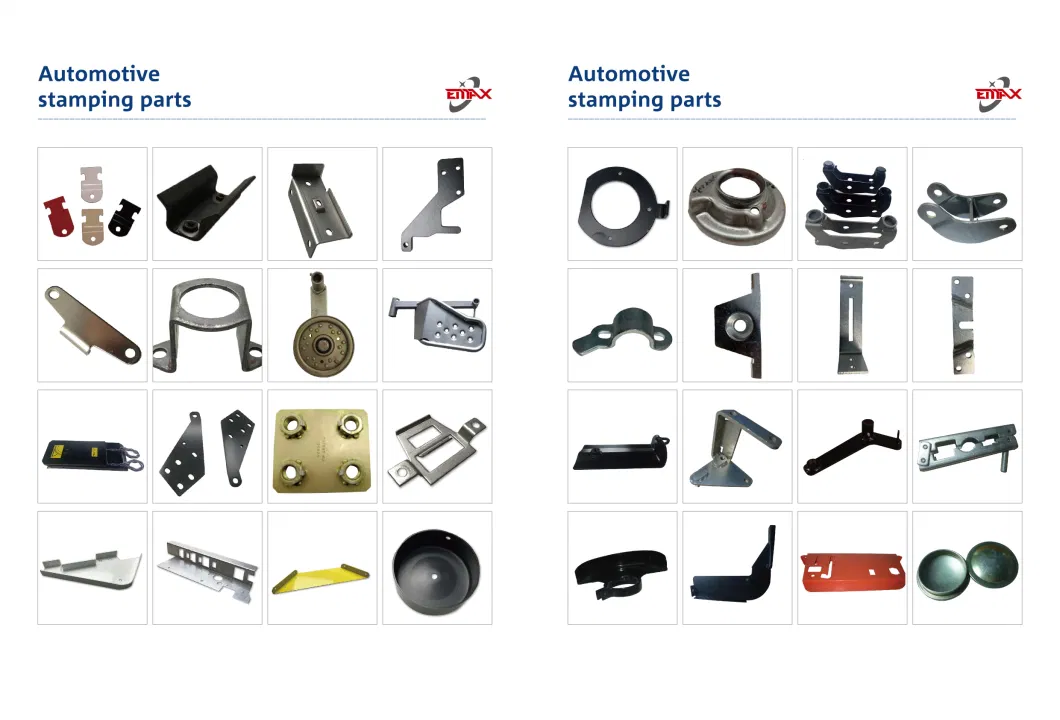

A: Power line hardware, mental bending parts, machine parts, punching parts, agricultural machinery spare parts, trailer spare parts, furniture parts...

Round Nut DIN 548 Adjustable Fixing Ring

Crafted to meet DIN, ASTM, and ISO standards, our heavy hex slotted nuts deliver reliable fastening performance for critical industrial applications. Available in sizes from M8 to M68, these nuts are manufactured from high-tensile carbon steel (Grade 8.8/10.9) or corrosion-resistant stainless steel (304/316), with optional zinc plating for enhanced protection.

Technical Specifications:

✔ Material Excellence

Carbon Steel: Grade 10.9 (ISO 898-1) | Yield Strength: 940 MPa

Stainless Steel: 316 (ASTM A193) | Salt Spray Resistance: 1000+ hours

Zinc Plating: 5-8μm coating thickness (ISO 4042)

✔ Precision Threading

Thread Standards: UNC, UNF, BSW

Slot Width: ±0.1mm tolerance

Dimensional Compliance: DIN 981 / ASTM A563

Industrial-Grade Performance:

Vibration Resistance: Nord-Lock washer compatibility

Temperature Range: -50°C to +300°C (stainless steel version)

Certifications: ISO 9001, CE, SGS (batch-tested)

Typical Applications:

• Power transmission tower assembly

• Heavy machinery maintenance

• Structural steel connections

Why Choose Our Nuts?

Material Flexibility: From economy carbon steel to marine-grade stainless

Custom Solutions: Laser etching, special coatings, and non-standard sizes

(Standard packaging: 25kg cartons | Custom packaging available)

Q & A

1. Q: What Types of Your Company?

A: We're a foreign company with our own factory. That is, an integrated set of industry and foreign trade.

2. Q: What Types that Your Company's Manufacturing?

A: OEM/ODM, logo printing and new product's volume production.

3. Q:What's Your Main Products?

A: Power line hardware, mental bending parts, machine parts, punching parts, agricultural machinery spare parts, trailer spare parts, furniture parts...